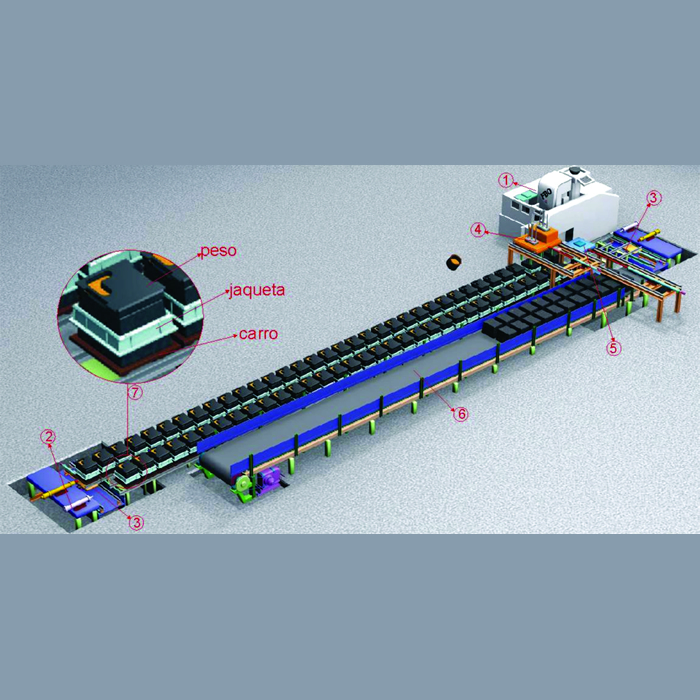

Molding System

The Sinto Brasil´s Molding System is the most complete and compact solution for flaskless molding.

A set of fully integrated components ensure efficiency increase, accuracy and productivity in your foundry.

The molding is done by the molding machine (1), which, through the blowing or aeration sand fill and hydraulic squeeze system, guarantees high and homogeneous hardness and resistance over the entire surface of the mold.

After molding, the mold is transferred to the Handling System (2) where it is poured and transferred, by pneumatic or hydraulic cylinders, to the Belt Conveyor (6), where the cooling is completed.

The System also includes: Two Transfer Cars (3), Weight and Jacket Transferr Device (4), Mold Push Off (5), Pallet Boogie, Jacket and Weight Set (7), in addition to the Electrical Command and Control System, integrating and monitoring the entire installation.

Mold dimensions: from 450 x 350 x 120/120 mm

Production: from 80 to 300 molds / hour.

For more information consult our Sales Department. We have exactly the Molding System that you need.

We have exactly the Molding System that your foundry needs.