CHUTE COATING

THE BEST OPTION FOR YOUR EQUIPMENT PROTECTION

The parts of the equipment that are exposed to abrasion, must be adequately protected to prevent their premature wear. The quality of these linings is vital to ensure longevity, reduction of maintenance costs and equipment availability. With the use of high-quality Sinto casted linings, you can increase the interval between stops to replace this component, due to its high durability combined with the consistent quality of our products, ensuring the linearity of the frequency of replacement needs. As a result, we minimize the cost of the coating itself and the need for manpower per ton handled, yet having a large gain due to maximization of available hours of the equipment.

SPECIFIC SOLUTIONS FOR EACH APPLICATION

After several researches and tests in our factory and in the field with our customers, we developed through the collected information and parameters, unique alloys and materials for linings in areas of chute, enabling better performance and durability of the parts, joining technology and quality.

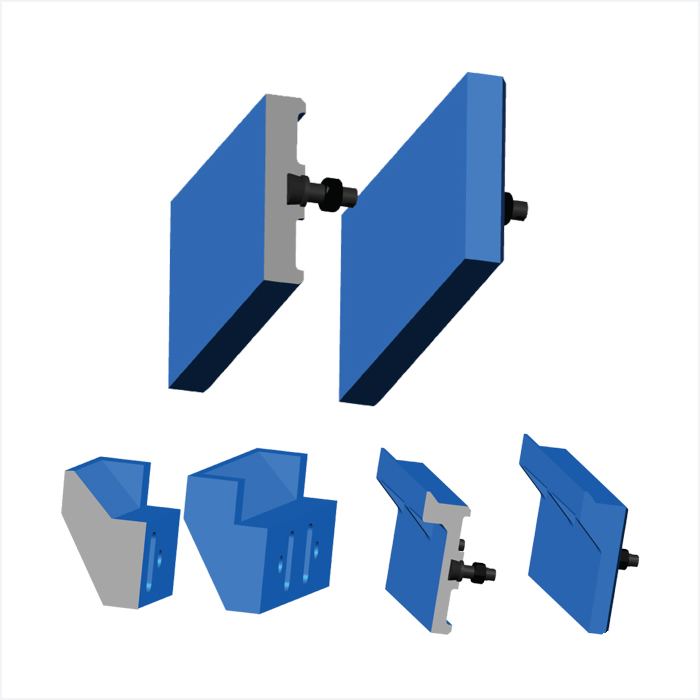

BLIND COATING

We seek to solve through this coating some problems that we found in our research, as concentrated wear in chute linings by the formation of preferential flow path due to the fixing holes. We designed a blind coating fastened through machined screw in a metallic insert, completely eliminating the formation of concentrated wear on the points of attachment, thereby enhancing the durability of the part and decreasing the amount of part replacements.

“STONE BOX” COATING

• To reduce the rate of ore flow in the chute.

• Elimination of the formation of preferential flow path through the coating fixation without the need for holes in the face of attack.

• To minimize premature wear of the coating by eliminating the formation of edges, through the accumulation of own material, which protects the coating against abrasion of the material flow.

With this coating we reduce the rate of ore flow in the chute, with the formation of obstacles with the manipulated material itself accumulated in the cavities designed for this purpose, drastically reducing the wear of the coating, giving a great increase in its useful life.