PARTS AND SERVICES

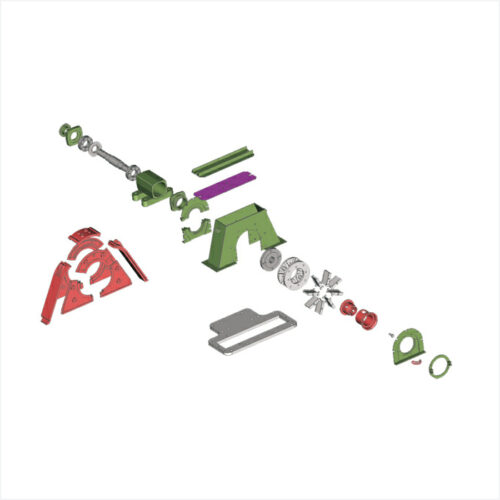

Control Box

If grit does not reach components that are supposed to be blasted, cleaning will not take place and the overall efficiency of the process will decrease. Such efficiency depends upon the direction of abrasive over components, a function performed by the control box inside the turbine. Shape of turbine jet stream can be directed to any position through a 360 degrees control box adjustment. Once adjusted, grit will continue to be thrown at the correct direction up to the point of degradation caused by opening wear. Wear at one of the edges increases the control box opening and the grit flow: additional equipment parts are reached and a smaller grit quantity hits the hot spot. Such situation provokes premature wear and decreases blasting efficiency.

MAXIMUM WEAR (depends upon turbine model)

Control box is one of the parts subject to natural wear from turbine operation. It is more itense at the edges. When a 12 mm wear is seen and varying with the turbine model, control box must be replaced by a new one.