Testimonials

JCB do Brasil (Brazil)

They opened their Painting Complex in Brazil in 2012.

In recent years, the concept of the painting process in general has undergone very big changes, especially in terms of product quality, including visual aspects. In response to these changes, JCB do Brasil, the country’s third largest manufacturer of construction machinery for the civil sector, opened their Painting Complex in 2012.

Before opening the Painting Complex, JCB sent all of their products to external suppliers, so they had to manage the entire supply chain. With their extensive product range, it was very complex to ensure that different suppliers with different equipment and staff were able to provide the same standardized product. Amid this, they received references from shot blasting companies, and Sinto was one of them.

“Sinto was very willing to cooperate with the best development, since the beginning. This was a big difference from other companies.”

From the beginning, Sinto’s stance regarding product development was different from other companies. JCB has products from 5 kg to 4 tons, with different dimensions and processes, that all have to achieve the same high product quality. Their Manufacturing division explains, “Sinto was very willing to cooperate with the best development, since the beginning. This was a big difference from other companies.”

Another important factor was distance. With such complex equipment, they wanted to have Sinto close to their factory in case of an eventual need for service and technical assistance.

Maintenance was another relevant point. Due to the equipment size, they expected much higher maintenance costs than what they actually have. With the exception of parts that naturally wear out over time due to the manufacturing process, they have not had any occurrences during the last six years that would interrupt their production chain or interfere with their business.

They hope manufacturers will provide new solutions for fire safety.

One of the major risks of blast equipment is the risk of fires. For installation of the new equipment, JCB was looking for a machine that has fire prevention and countermeasures. Some options based on CO2 and based on lime were offered, but due to the cost, they proved difficult to include in the machine. JCB believes this is an opportunity for all manufacturers in the field to propose new solutions to this critical fire safety issue.

The prospects for JCB are very good.

Recently, an investment of 100 million BRL was announced for the plant, in order to support an increase in their product capacity. “This will increase our product portfolio for our Brazilian market, too,” JCB states. “Prospects are good.”

Since the beginning of the Painting Complex in 2012, Sinto has been very willing to work with JCB, and JCB believes that Sinto retains this culture. “In an eventual need of a new investment, surely we will look at Sinto again.”

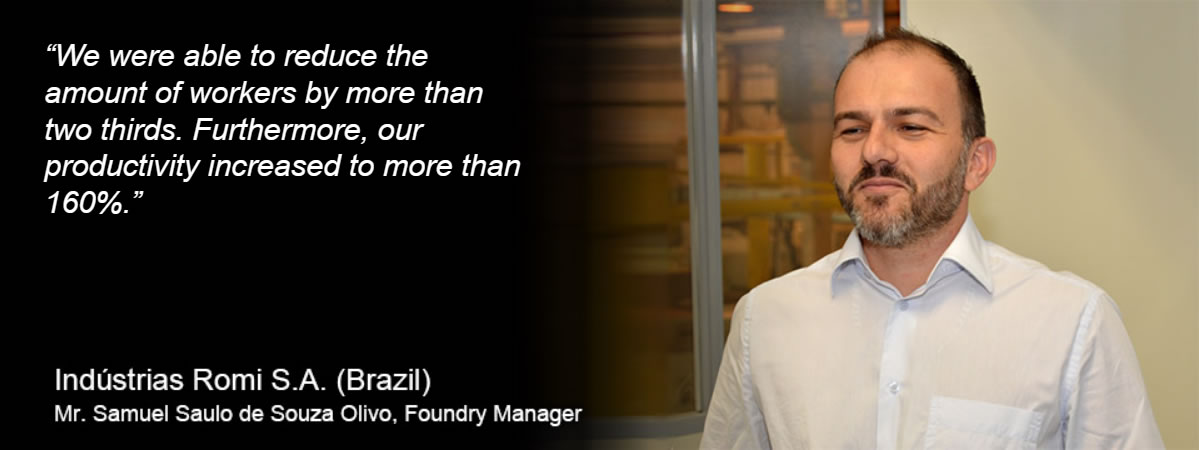

Indústrias Romi S.A. (Brazil)

It isn’t enough to just be professional. You must have passion.

Romi produces machine tools, plastic processing machines, and casted and machined parts. They believe that in order to be successful, it isn’t enough to just be professional; you must have passion. Based on this belief, they use their creativity to raise their competitiveness in markets within and beyond Brazil. With their casted parts, they serve not only the automobile industry, they are also developing in the agricultural equipment industry, which uses large parts.

They reduced the amount of workers by more than two thirds. Furthermore, their productivity increased to more than 160%.

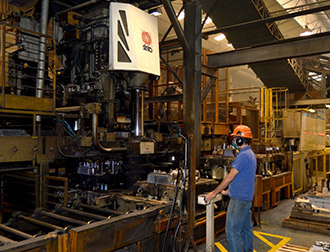

Previously, Romi owned an old molding machine that they had been using for over 45 years, which had a limited flask size. Over the years, other shapes and sizes came into demand, and their limitations with flask size reduced their ability to compete in the market. Thus, they chose to purchase a new molding machine.

Upon deciding to purchase a new machine, they did research and looked at all molding machine manufacturers. As a result, they confirmed that Sinto was number one in sales of molding machines. Ultimately, the decision to go with Sinto came from their leadership in the market.

After installing the machine, they were able to reduce the production of defective parts 30% to 35%, and compared to the old machine, they were able to reduce the amount of workers by more than two thirds. Other important effects were that their productivity rose to more than 160%, and their average mold weight increased to more than 120%.

Thanks to the increase in productivity, Romi managed to win a customer that they were competing over with another foundry, while still working with existing customers. Not only have they gotten new customers, but they have also increased their share of current customers after acquiring the Sinto equipment.

They are taking an aggressive stance to develop in new markets.

Romi has been expanding their supply range, and they are working with customers with whom they have had no interaction before. They continue to work hard in their main business, the automotive market, and they hope to take an aggressive stance as they enter into the construction equipment business and strengthen in the agricultural equipment market, where they did not have much influence in the past.

They are also proceeding with conversations in various markets, such as the wind power generation market. For different markets there are different casting needs, and Romi has good prospects for supplying casted and machined parts to those markets, both nationally and internationally. Romi will continue to work hard to create demand for castings from now on.