PARTS AND SERVICES

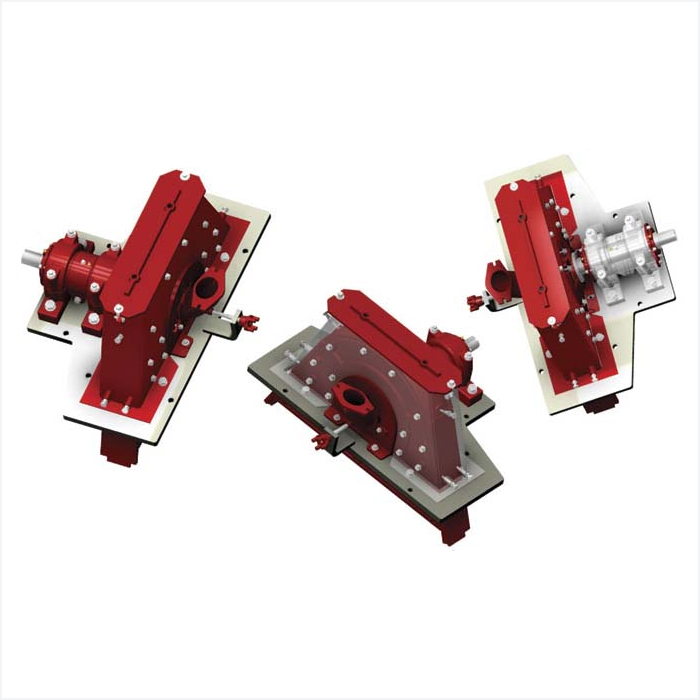

RLM Turbines

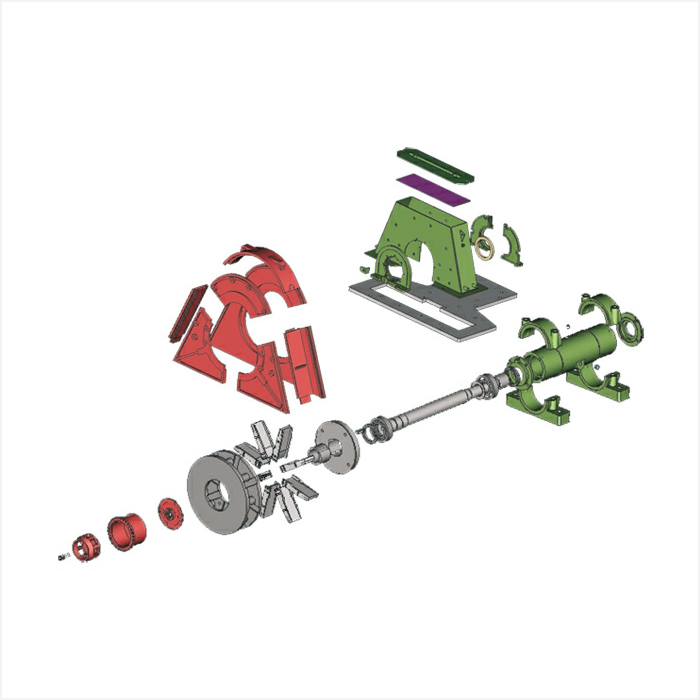

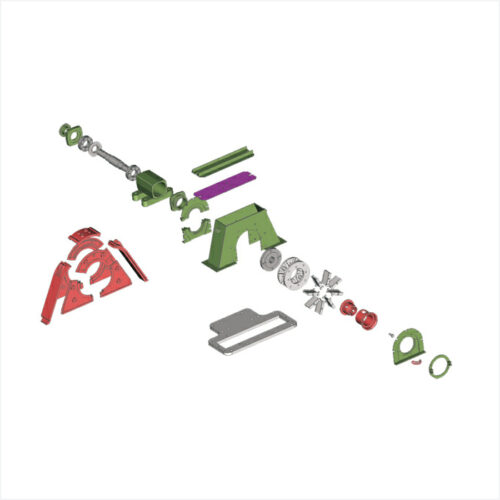

RLM turbines have been engineered with computer simulations and intensive field tests, with the final evidence of comparable better performance due to larger abrasive load capacity per time unit. Blades were designed with a specific abrasive entrance curvature point. Such technical feature provides a controlled throw with additional abrasive kinetic energy and softer operation combined with precise geometry, plus minimum wear.

Blade assembly is made easy through internal openings at the wheel discs and turbine centre. Locking is obtained by centrifugal force and no springs, pins and screws are necessary. Dismantling is also very simple, through the removal of feeder, impeller, control box and centralization disk and without any special tools. An additional advantage of that architecture lies at the inspection of vital turbine parts, able to be fully performed during the above mentioned operation.

Our RLM turbines are those better accepted in all markets and account for the largest quantity presently operating in Brazil. 30 years of successful presence in the Brazilian Market are the result of its reliability and strength!!!